Designing healthy buildings means specifying healthier products.|||

Designing healthy buildings means specifying healthier products.|||

It’s no secret that awareness of the climate crisis has increased over the last year or so. From Greta Thunberg’s inspiring speeches to world leaders or Extinction Rebellion taking over the streets of London, our planet and our impact on it has been top of the news agenda.

But away from the public spotlight, many businesses have also started to pivot towards making environmental considerations of greater importance in their decision making than ever before.

And with the built environment being one of the main contributors to the UK’s carbon footprint – 40 percent according to the UKGBC – property must play its role. This is starting to happen across the spectrum, with investors, developers, and business occupiers all realising that they must take action.

For example, at January’s Association of Real Estate Funds (AREF) environmental, social and governance (ESG) standards were voted as the primary issue to affect property funds in 2020.

Architects and designers have a crucial role to play in ensuring that the buildings we design and build today are fit for the cleaner tomorrow, and designing healthy buildings means specifying healthier products. We must be much more stringent about the materials we choose.

Read more: How we can design carbon-neutral offices

Within the design world, the most impactful decisions are still too often made in the dark, with little information about construction materials’ environmental impacts being easily available.

For example, synthetic chemicals, such as Polyvinyl Chloride (PVC), have often been the go-to for plastics in construction. But although PVC is strong, durable, versatile and lightweight, it is not biodegradable or degradable so will retain its form for decades, causing a number of environmental issues.

Additionally, substances called phthalates are added to PVC to make it flexible, which studies have shown are hazardous for our environment and our health, so it is imperative that an alternative is suggested in the design and construction process.

We now know that many other chemicals typically used to create other materials are just as problematic. Formaldehyde, for instance, which is commonly found in polymers used in plywood and carpet manufacture, has been found to be a common irritant to the skin; and flame retardant materials have been linked to a number of severe health risks such as cancer and birth defects.

To tackle this, Perkins and Will’s global practice ignited the industry movement towards healthier building materials with our Precautionary List published in 2008, and the Transparency website launched in 2011. Updated, this now acts as a user-friendly digital database allowing design professionals to search for key substances and chemicals of concern using filters like project type, product type, and health and environmental impact.

Read more: Perkins and Will’s Toronto office is designed for a healthy workplace and culture

We believe, as architects, it is our responsibility to lead the revolution and to influence manufacturers to review the content of their products, as well as the manufacturing process itself.

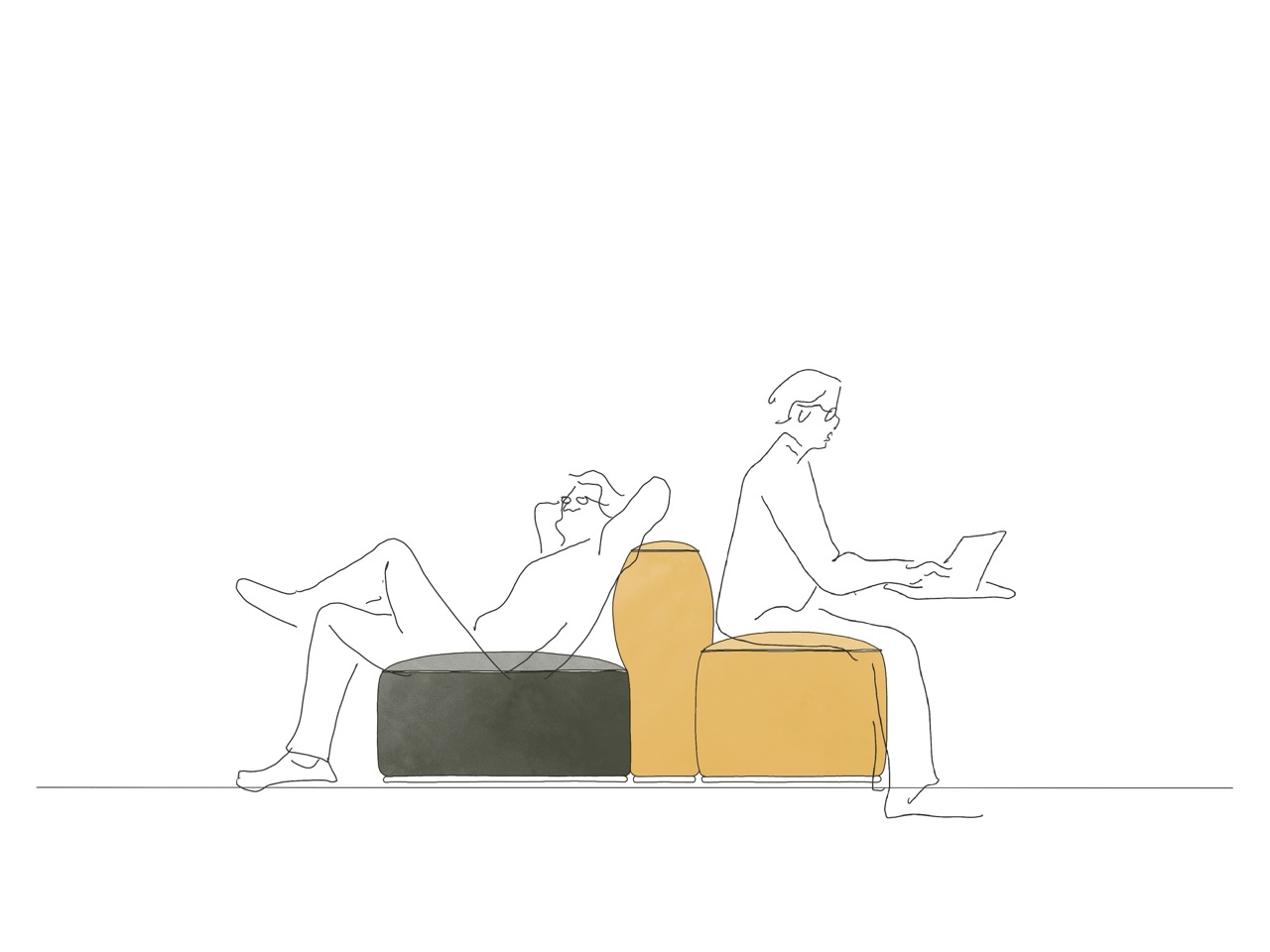

The whole supply chain, from furniture manufacturers to fit-out specialists, will have to adapt and understand the environmental health impact of the materials they use.

This is especially true when you consider consumers – and therefore employees- are asking more questions about where products are from.

Indeed, what is good for the environment may also be good for the bottom line, with Accenture finding half of consumers would pay more for sustainable products designed to be reused or recycled.

For our end user clients, certification process like LEED, BREEAM, and WELL exist and take up is rising. Points are available for products with EPDs (Environmental Product Declarations) and HPDs (Healthy Product Declarations), and these products can be specified even if your client is not pursuing certification.

Here are three tips on how to get started:

1. Ask manufacturers and suppliers for their EPDs and HPDs. If these are not readily available, beware! And look for alternatives.

2. Ask questions about the manufacturing process itself, and its carbon footprint.

3. Join the conversation about material health and be a positive influencer for change.

Principal and Design Director at Perkins and Will’s London Studio shares her thoughts on material health within office design