Brodie Neill sitting on his Pleat bench, part of Made in Ratio’s second collection|Tetra, an oak shelving system made from multiple stacked trapezoids|A felt stackable stool made from recycled PET. The stool is also recyclable|Prism, a glass a steel table: “Like a Noguchi coffee table, but harder-edged”|The Pleat bench, made from Corian, neatly overlaps at the ends to form its feet|The Stem stool is a curvy piece of Corian set on top of a swivelling base|Supernova’s trestles can be placed in different positions to alter its height|Italian glassblowers make the rounded, flower-like Cumulous pendant|The looping E-turn fibreglass bench, made for Kundalini|Glacier, a limited-edition chaise made from 300kg of clear glass|Inspired by a shell, the Cowrie rocker has a satisfying simple outline|Like the rocker, the Cowrie chair is made from a single sheet of plywood|The Reverb chair expressed Neill’s interest in parametric design…|…also explored in Made in Ratio’s Matrix coat stand, a woven thread of steel||

Brodie Neill sitting on his Pleat bench, part of Made in Ratio’s second collection|Tetra, an oak shelving system made from multiple stacked trapezoids|A felt stackable stool made from recycled PET. The stool is also recyclable|Prism, a glass a steel table: “Like a Noguchi coffee table, but harder-edged”|The Pleat bench, made from Corian, neatly overlaps at the ends to form its feet|The Stem stool is a curvy piece of Corian set on top of a swivelling base|Supernova’s trestles can be placed in different positions to alter its height|Italian glassblowers make the rounded, flower-like Cumulous pendant|The looping E-turn fibreglass bench, made for Kundalini|Glacier, a limited-edition chaise made from 300kg of clear glass|Inspired by a shell, the Cowrie rocker has a satisfying simple outline|Like the rocker, the Cowrie chair is made from a single sheet of plywood|The Reverb chair expressed Neill’s interest in parametric design…|…also explored in Made in Ratio’s Matrix coat stand, a woven thread of steel||

Complex and curvilinear, Made in Ratio’s debut collection fused digital design with hand-making. Now, its Australian-born, London-based designer is heading to Milan with a new bag of tricks…

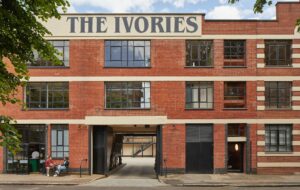

There is an underlying calmness to Brodie Neill’s Clerkenwell studio. Residing at the top of a seemingly endless stair, the stark whitewashed brickwork, matching furniture and dark wood floors are low key to the point of reticence. Neill’s small team work and chat quietly while Britpop fizzles rather than blares in the background. With Milan’s Salone del Mobile around the corner, by rights it should be a madhouse.

At this year’s fair, the Australian, who has been based in London for nearly ten years, will unveil the second wave of furniture made for his Made in Ratio brand.

Everything seems to be in hand. The new products, clustered in a far corner, are present and correct, barring a small felt stool, which Neill assures is on the way.

If the studio is feeling the pressure, it is performing a first-class job of hiding it. Perhaps Neill and his team are reaping the benefits of self-production rather than putting their faith in the big Italian brands’ opaque operations. “Some designers will send a scribble and the manufacturer almost has to interpret that. Six months later they’re in Milan being photographed next to it,” he says.

Aside from some small prototyping models, and an assortment of samples lining the windowsill like beach mementoes, the place is pretty tidy.

The focus errs toward deskbound activities rather than a hands-on workshop. But Neill is far more than mere theoretician. Made in Ratio’s website is littered with photographs of Neill manipulating cardboard, inspecting glassblowing moulds, bending wood… His latest range makes great play of processes and materials. The designer points to a felt blob, a pebble-sized version of his curvesome Remix chaise longue from 2008, which prompted the demise of his washing machine. “It bust after, like, 500 washes. I had to call up the landlord and pretend it was something else that broke it,” he says.

Fresh-faced and enthusiastic, the designer talks through his collection, which he will launch, with typical ambition, at a restaurant and cocktail bar off Via della Moscova. “A lot of these pieces are designed to fill in those gaps from the first collection,” he says. In material terms there is something for all tastes: a Corian bench and bar stool, a glass and steel coffee table, timber modular shelving and a small stool made from recycled PET felt.

Neill admits the intention is to widen the appeal of the brand and the marketing material supports this. Whereas the first Made in Ratio products, shot on white plinths in a Bermondsey foundry, had an edgy quality, they also felt a little aloof. In contrast, Made in Ratio mark II has wholeheartedly embraced the consumer world. The trapezoidal Tetra shelving, like all the new products, is shot in context and festooned with houseplants and science textbooks, referencing its geometrics. The offset Prism coffee table, meanwhile, plays with rotational symmetry while harnessing pure, architectural materials. “It’s almost like a Noguchi coffee table, but harder edged,” says Neill. The PET stool is an entry-level product and a higher volume, contract piece.

“A lot of these new pieces are designed to fill in those gaps from the first collection”

Of the new work, the Pleat bench, along with Stem, the biomorphic barstool, which leans forward enquiringly like a man on the balls of his feet, are closest to Neill’s early parametric adventures. Made in Ratio, Neill explains, aims to find the perfect apportion of digital design and rigorous hands-on craftsmanship to create striking and affordable products.

It was not always thus. Earlier in his career, Neill’s swooping designs captured with gleeful intent the boom times before the 2008 financial crash, when everything from architecture to seating was striving to be iconic.

The designer, who founded his practice in 2005, plunged into the zeitgeist, exhibiting a monolithic chaise-longue at SuperDesign in 2008 alongside fellow member of the parametric mafia Ross Lovegrove. “It was the rise of the limited editions when things got just a bit mental,” he says. What seemed so vital then now looks a bit dated. With the austerity age ushering in a worthy craft aesthetic, it’s as if prune juice has replaced champagne cocktails.

If one were looking at Neill’s portfolio for a sign of those times, the bulbous Reverb chair, constructed from a lattice of different-sized bent wires, fits the bill.

Visually seductive, the piece was unsuitable as a volume product (Neill approached a metalwork company in Peterborough, which said it could not be done). You can buy one, but it is handmade in Italy and costs £25,000. A folded steel version – a masterclass of engineering that made Time magazine’s Design 100 in 2008 – showed how wide the gulf between form and function had become.

The trip to the Midlands, however, was far from time wasted. As Neill steered his designs in a more rational direction for the Made in Ratio brand, he revisited Peterborough with an early incarnation of a coat stand he was working on, Matrix. Essentially a twisting diagrid, the form was initially met with a dollop of scepticism. “They were equally stumped by it, but by analysing it on computers and using model-making we managed to break it down into repetitive forms.”

Matrix stands, like a scaled-down version of Moscow’s Shukhov Tower, in the corner of the studio, camouflaged by scarves and overcoats. “It is a materials, digital and hands-on process, made possible by technology,” says Neill. “Once the research and development into how it all goes together is done, you are only 50% there. The finishing is quite intense and that is where the handmade part comes in.”

It was a similar tale for Supernova, a glass table with recycled aluminium legs (window frames in a former life) that resemble a molecular structure. Supernova is Made in Ratio’s most successful product, and while the name suggests some kind of cosmic vision, in reality Neill was looking closer to earth for inspiration. “It was more physical than conceptual; we were trying to create a jack shape, so that any which way it lands it would make a structure.

Then we did the development and mathematics and created this form.” Neill demonstrates, using a tiny model, how the legs are comprised of two moulded aluminium elements joined together, which can be set vertically or horizontally depending on how high you want the table. The join is expressed rather than hidden – a maker’s mark. With design realised, Neill worked with a marine parts manufacturer in Southampton to get it made. “With something like this you could easily go to China or eastern Europe, but that is void of the storytelling, really. Plus it would be very difficult to do something like that without that frequent communication with the maker.” Neill prefers to oversee and question every stage of a product’s development.

Neill’s initial work was a celebration of digital design and the impossible forms it yielded, which developed into an exploration of symbiosis between tried and tested techniques, bent wire, for instance, or glassblowing, and 21st-century technology.

The designer likens it to a bridge linking the reliability of 1950s modernism to a new pioneering era.

Materials have become more intrinsic to the design, but this has not wholly diluted the organic aesthetic.

If anything, the more traditional materials have added significance, as is the case with the Cowrie chair, which captures the energy of previous products like the E-turn bench, an endless loop of fibreglass. Neill’s renewed vigour for craftsmanship recalls his student days at the University of Tasmania where the onus was a little “crafty-wafty” as he describes it. “It was a designer-maker approach, almost fine art. Whatever you designed you had to make. The only way I could learn digital design was to take an animation class rather than a CAD class. I still use that program today because it gives you more freedom than an engineering program. It forces you to work out for yourself whether things are possible.”

“The only way I could learn digital design was to take an animation class rather than a CAD class”

Though awakened to digital design, it was only when the young designer won a place at Rhode Island School of Design that he was fully able to develop his skills.

After graduation, Neill moved to New York and took a job at L’Oreal, which hardened his resolve to set up his own company.

In 2005, he had a stand at the Salone Satellite and caught the attention of Italian lighting brand Kundalini, with whom he developed the Morphie pendant lamp and then the E-turn. “That was a real ‘what if’ moment. It launched at the Salone and on the first day of the fair it was on the front page of the local paper.” Although Made in Ratio is Neill’s immediate focus, the designer has retained relationships with manufacturers. The reason being that products like the Clover light, also designed for Kundalini, would fail to fulfil their potential without the backing of a large manufacturer.

The designer’s spontaneity means he works best when a company allows him creative freedom.

So far, brands have been happy to oblige lest they kill the magic with too many boundaries. Neill reveals that even as a teenager building furniture in his parents’ shed, he was never the type to simply copy an existing design. “It would never look like the picture,” he says. “I would always change things as I was going along.” This willingness to experiment, albeit with new forms, materials or technology, is what sets Neill apart from the current crop of young designers. It also sets him up for criticism, particularly when he enters the rarified world of limited edition collectors’ items. Glacier, a jaw-dropping 300kg chaise longue made from moulded glass courted controversy with many, particularly on the net, who saw it as the antithesis of what design should strive for. Certainly Glacier was far from democratic, but the sustainability argument falters somewhat when compared with a mass-produced, poorly made object that crumbles after a year. Although he says he will continue to design unique products like this, the designer’s work has become far more attainable without sacrificing its individuality. One gets the sense his work will continue to evolve, but for the moment he remains a welcome tonic for an industry that has lost its nerve. It just might be that designers like Neill can provide the impetus that help recapture its vitality.